Modern üretim hatlarında etiketleme artık sadece bir şişeye etiket yapıştırmaktan ibaret değil. İlaç, kozmetik ve yiyecek-içecek gibi sektörlerde etiketleme sürecinin doğruluk, tutarlılık ve verimlilik açısından katı gereklilikleri karşılaması gerekiyor. İşte tam da bu noktada... yatay yuvarlak şişe etiketleme makinesi kritik bir rol oynar. Yüksek hassasiyet sağlaması ve malzeme israfını azaltması sayesinde, operasyonlarını optimize etmek isteyen üreticiler için vazgeçilmez bir araç haline gelmiştir.

1. Etiketleme Doğruluğunun Önemi

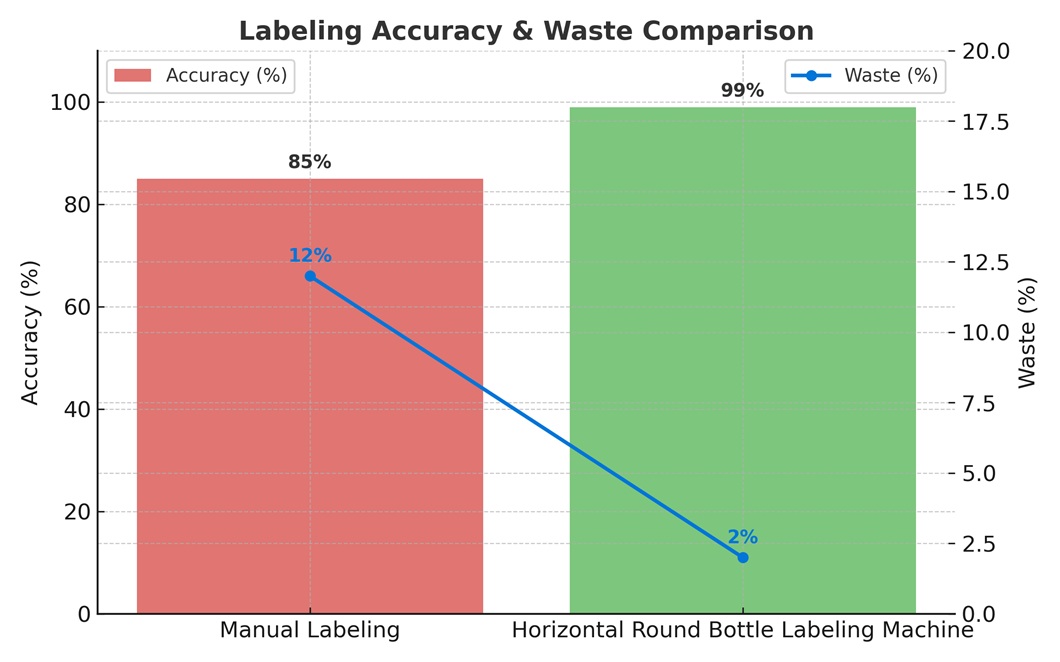

Etiketleme doğruluğu, hem marka imajını hem de yasal uyumluluğu doğrudan etkiler. İlaç gibi sektörlerde, küçük bir uyumsuzluk bile okunamayan dozaj bilgilerine veya yasal uyumsuzluğa yol açabilir. Kozmetik ve içeceklerde ise, kötü uygulanmış etiketler müşteri güvenini zedeleyebilir ve raf çekiciliğini azaltabilir.

Yatay yuvarlak şişe etiketleme makinesi, hassasiyetin en kritik olduğu küçük çaplı şişeler, flakonlar ve ampuller için özel olarak tasarlanmıştır. ±1 mm gibi dar bir doğruluk toleransına sahip bu makineler, üretim hızından bağımsız olarak her etiketin mükemmel şekilde hizalanmasını sağlar.

2. Yatay Etiketleme Makineleri Yüksek Hassasiyete Nasıl Ulaşır?

Manuel veya yarı otomatik yöntemlerle karşılaştırıldığında, otomatik yatay yuvarlak şişe etiketleme ekipmanı Tutarlı sonuçları garanti eden gelişmiş özellikleri entegre eder:

Bu teknolojiler, yüksek hacimli üretim çalışmalarında bile insan hatasını ortadan kaldırmak ve tutarlı etiket yerleşimini korumak için birlikte çalışır.

3. Otomasyonla Etiketleme İsrafını Azaltma

Etiket israfı birçok fabrikada yaygın bir sorundur. Yanlış hizalanmış veya buruşuk etiketler genellikle şişelerin atılmasına ve ek maliyetlere yol açar. yüksek hassasiyetli şişe etiketleme makinesi, atık iki temel yolla önemli ölçüde azaltılır:

1) Doğru uygulama – daha az baskı hatası ve yanlış yerleştirme daha az malzeme kaybı anlamına gelir.

2) Optimize edilmiş etiket kullanımı – gelişmiş yazılım, her etiket rulosunun maksimum kapasitede kullanılmasını sağlayarak gereksiz israfı azaltır.

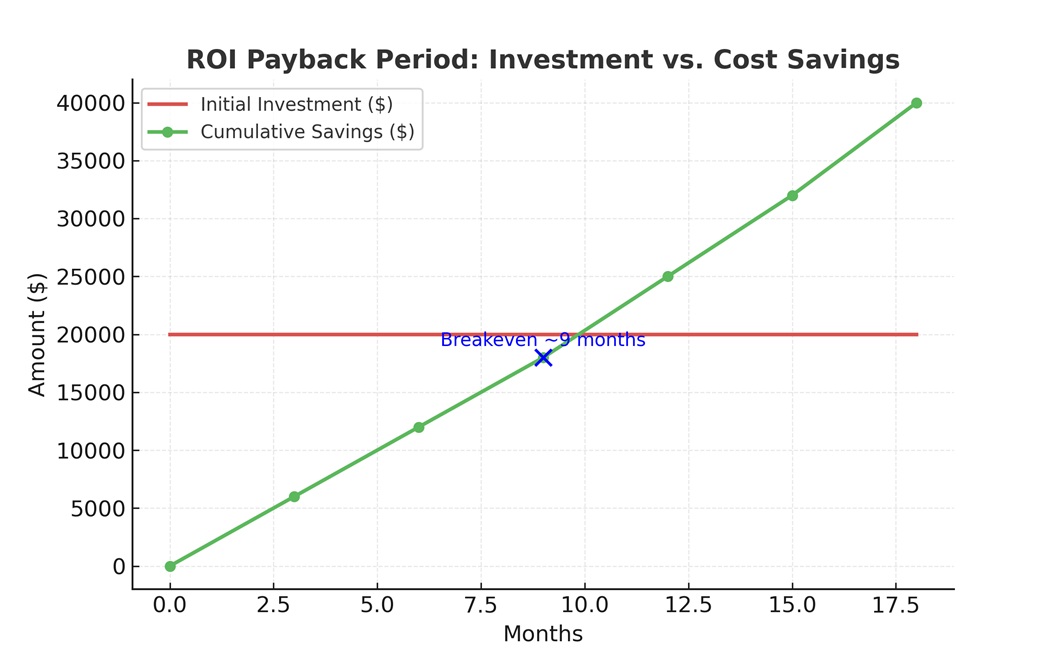

Üreticiler, hem etiket malzemesi israfını hem de ürün reddi oranlarını en aza indirerek etiketleme ekipmanlarından daha güçlü bir ROI (Yatırım Getirisi) elde edebilirler.

4. Yatay Yuvarlak Şişe Etiketleme Makinelerinden Faydalanan Temel Endüstriler

Benimsenmesi Yatay Yuvarlak Şişe Etiketleyiciler birçok sektörde büyüyor:

Bu sektörlerin her birinde, etiket kalitesini artırırken israfı azaltmak, karlılığı ve müşteri memnuniyetini doğrudan artırır.

5. Üreticiler için Uzun Vadeli Faydalar

Otomatik yatay yuvarlak şişe etiketleme makinesine yatırım yapmak, doğruluk ve atık azaltmanın ötesinde uzun vadeli değer sağlar:

Daha düşük işletme maliyetleri – daha az işçilik ve daha az etiket atığı.

Ölçeklenebilirlik – büyüyen üretim hacimlerine kolayca uyum sağlar.

Uyumluluk güvencesi – tutarlı etiketleme ile düzenleyici standartları destekler.

Geliştirilmiş marka imajı – profesyonel, yüksek kaliteli paketleme hizmeti sunuyoruz.

Günümüzün rekabetçi pazarında, üreticiler etiketleme süreçlerinde verimsizliklere tahammül edemezler. Yatay yuvarlak şişe etiketleme makinesi, etiketleme doğruluğunu artırmanın yanı sıra israfı da en aza indirerek işletmelerin maliyet tasarrufu elde etmelerine ve güçlü bir marka imajını korumalarına yardımcı olur. İster ilaç, ister gıda ve içecek, ister kozmetik sektöründe olun, otomatik şişe etiketleme ekipmanına yatırım yapmak, daha fazla verimlilik ve kârlılığa doğru atılmış akıllıca bir adımdır.

Çalışma Zamanı

Bilgilerinizi günün 24 saati alın

Pekin saati: Pazartesiden Cumaya 9:00-17:30